Covalent bonds between carbon and heteroatoms, e.g. sulfur or nitrogen is a generic phenomenon in eco-systems and artificial materials. Our modern society is heavily dependent on industries using carbon as energy carriers, either combustion of depleting fossil fuels or carbothermic metallurgy. Such processes inevitably cause huge coincident carbon, sulfur and nitrogen oxides emissions (with the latter two being minor in the corresponding flue gas), which is the main source of climate change and atmospheric pollution such as acid rains and atmospheric particulates.

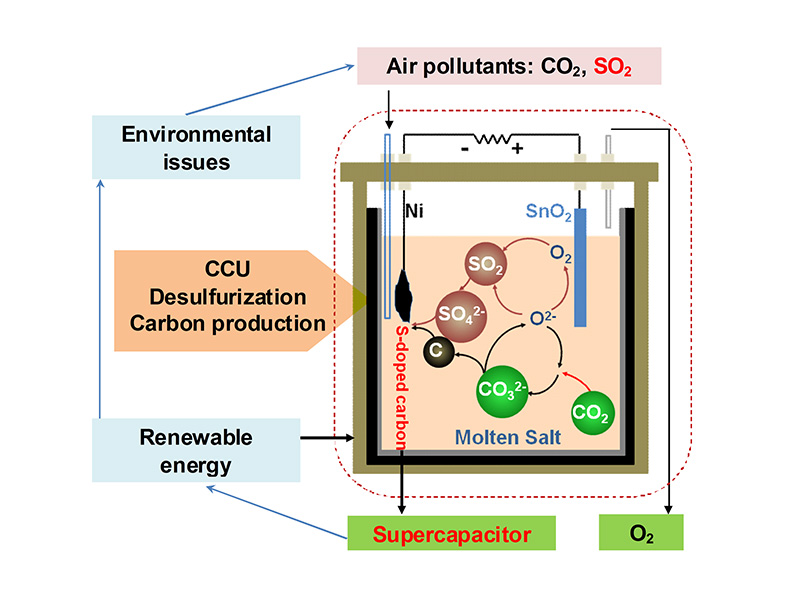

A main challenge in practical implementation of CO2 Capture and Utilization (CCU) technologies is to avoid inconvenient poisoning effects of accompanied sulfur oxides and/or nitrogen oxides to catalysts, which, however may be tackled effectively, as reported in our recent article (Flue-Gas-Derived Sulfur-Doped Carbon with Enhanced Capacitance, Advanced Sustainable Systems, 2017, adsu201700047), by using one-pot molten salt capture and transformation. In molten Li2CO3-Na2CO3-K2CO3-Li2SO4 eutectic at 475 °C, direct capture and electro-reduction of synthetic flue gas containing CO2 and SO2 into porous sulfur-doped carbon and O2 with superior energy storage capability by using a SnO2 inert anode and a nickel cathode. This process is amendable to be driven by electricity from renewable energy like solar power or from off-peak electricity. In such a scenario, an affordable and high-flux CCU technology integrating with deep-desulfurization and preparation of advanced carbon/O2 is of practical promise in terms economic viability and environmental benignity. It is believed that this process can be extended to capture and utilization of flue gas containing nitrogen oxides.

The forenamed strategy is apt to power plants and steel/iron –making sectors, by providing a close-loop solution in terms of energy, resource and environmental sustainability (See the figure). With input of electricity from renewable energy and flue gas, advanced carbon and value-added O2 are generated. The former is the key-enabling materials for diverse applications ranging from energy storage/conversion to environmental remediation. The latter, O2, can be fed back to combustion chambers for high-efficiency oxy-fuel combustion or back to blast furnaces in steel/iron –making sectors for purifying steel/iron.